When choosing the right aluminum tool case, most people focus on the exterior—durability, locks, handles, and design. But what’s inside is just as critical. The type of foam lining plays a major role in how well the case protects your valuable tools and equipment. Two of the most common options are wave foam (also called egg-crate foam) and flat foam. In this guide, I’ll compare wave foam and flat foam, helping you decide which is best for your aluminum tool case based on protection, functionality, and usage scenarios.

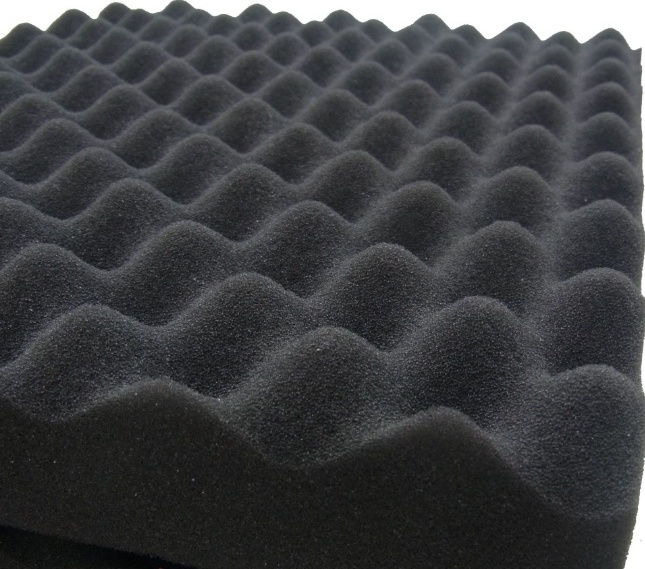

1. What Is Wave Foam?

Wave foam, commonly recognized by its egg-crate appearance, features a series of peaks and valleys that create a cushioned surface. It’s typically attached to the lid or the base of the aluminum tool case.

Advantages of Wave Foam:

- Excellent for cushioning irregularly shaped items.

- Absorbs shocks and vibrations effectively.

- Prevents tools from shifting during transport.

- Lightweight and flexible for various tool types.

Disadvantages of Wave Foam:

- Less precise than custom-cut foam.

- Not ideal for items that need a snug, fixed fit.

Wave foam is perfect if you frequently carry different tools and need adaptable cushioning inside your aluminum tool case.

Advantages of Flat Foam:

- Offers a clean, even surface for tool layout.

- Often combined with pick-and-pluck foam for custom fitting.

- Provides moderate cushioning and stability.

- Great for creating a neat, professional appearance.

Disadvantages of Flat Foam:

- Less effective in absorbing vibration compared to wave foam.

- Items may shift if not securely cut into the foam.

Flat foam is the go-to for anyone wanting a custom layout inside their aluminum tool case, especially for precision tools or electronics.

3. Wave Foam vs. Flat Foam: Side-by-Side Comparison

| Feature | Wave Foam | Flat Foam |

| Appearance | Egg-crate, peaks and valleys | Smooth, uniform surface |

| Shock Absorption | Excellent | Moderate |

| Vibration Control | High | Moderate |

| Tool Stability | Good for general protection | Best with cutouts for secure placement |

| Flexibility | Adapts to different shapes | Needs customization for perfect fit |

| Professional Look | Functional | Sleek and organized |

| Ideal Use | Transporting various items | Precision storage with custom layouts |

4. Which Foam Is Right for Your Aluminum Tool Case?

Choose Wave Foam if:

- You need versatile, ready-to-use protection.

- You frequently carry tools of different shapes and sizes.

- Shock and vibration resistance are top priorities.

Choose Flat Foam if:

- You prefer a clean, organized tool layout.

- You want to custom-cut foam to match specific tools.

- A professional appearance inside the aluminum tool case matters to you.

In some cases, manufacturers even combine wave foam (on the lid) and flat or custom-cut foam (at the base) for the best of both worlds.

5. Why Foam Selection Matters in Aluminum Tool Cases

Your portable tool case isn't just for storage—it's for protection. Whether you’re carrying precision instruments, electronics, or hand tools, choosing the right foam affects the longevity and safety of your items.

Wave foam is ideal for frequent transport and general protection, while flat foam excels in tailored organization and aesthetics. Investing in the right foam makes your aluminum tool case more than just a box—it becomes a dependable protective solution.

Conclusion: Make the Smart Choice for Your Tools

When selecting an aluminum tool case with Foam, don’t overlook the importance of the interior foam. Both wave foam and flat foam serve distinct purposes. By understanding their differences, you can choose the right solution that enhances protection, organization, and efficiency. If you're looking for a durable aluminum tool case with foam that fits your exact needs, feel free to explore our custom solutions.

Post time: Jun-26-2025