Barber Case

Aluminum Barber Case for Barber Clippers and Tools

♠ Product Description

Portable & Practical

This barber organizer case is thoughtfully designed with multiple slots to securely hold various barber tools, such as clippers, scissors, and combs. It features a removable and adjustable shoulder strap, making it easy to carry, display during work, or travel between appointments—ideal for mobile and professional barbers alike.

Spacious & Organized

With strategically designed compartments, this barber case maximizes internal space for better organization. Every inch is utilized to store clippers, trimmers, razors, and accessories efficiently. The layout helps barbers keep tools neatly arranged and easy to access, whether at a shop or on the go, enhancing work speed and professionalism.

Lightweight & Durable

Made of aluminum alloy, this barber case offers an ideal balance of strength and light weight. Compared to wood or plastic cases, it’s far easier to carry—especially during long workdays or travel. Its durable structure ensures protection, while the lightweight material minimizes fatigue for barbers constantly on the move.

♠ Product Attributes

| Product name: | Aluminum Barber Case |

| Dimension: | Custom |

| Color: | Black / Silver / Customized |

| Materials : | Aluminum + MDF board + ABS panel + Hardware + Foam |

| Logo : | Available for silk-screen logo / emboss logo / laser logo |

| MOQ: | 100pcs |

| Sample time : | 7-15 days |

| Production time : | 4 weeks after confirmed the order |

♠ Product Details

Handle

The handle on an aluminum barber case provides a firm, comfortable grip for carrying the case by hand. The handle’s ergonomic design reduces hand fatigue, especially when transporting heavy tools over long distances. The handle ensures convenience, ease of use, and added control when moving the case between salons, appointments, or events.

Lock

The lock system on an aluminum barber case is designed to keep your tools secure and prevent unauthorized access. These locks not only protect valuable clippers, scissors, and grooming accessories from theft but also prevent the case from accidentally opening and spilling contents. For professionals on the move, a strong, reliable lock ensures peace of mind and helps maintain tool security at all times.

Clapboard

The clapboard inside the barber case serves as a smart space organizer. It separates different sections of the case, allowing barbers to sort tools by function—like blades, scissors, and trimmers. This structure prevents tools from shifting during transport and keeps everything neat and easy to locate. It also protects delicate equipment by preventing direct contact or friction between items, helping extend the lifespan of professional barber tools.

Inside

The inside of an aluminum barber case is thoughtfully designed to accommodate various barber tools securely. The elastic band and fixing strap securely hold barber tools such as scissors, combs, and hair dryers in place, preventing them from shifting or colliding during movement. This reduces noise, protects delicate tools from damage, and keeps everything organized and accessible.

♠ Take a Closer Look at Excellence

High-Quality Professional Barber Case – Crafted for barbers who demand style, structure, and durability.

Sleek Aluminum Build – Lightweight, yet tough enough for everyday use.

Key Lock System – Security you can count on to keep your tools safe.

Smart Interior Design – Everything stays in place, from scissors to clippers.

The perfect storage solution for professionals who care about presentation and protection.

Watch the video to explore every angle and detail up close!

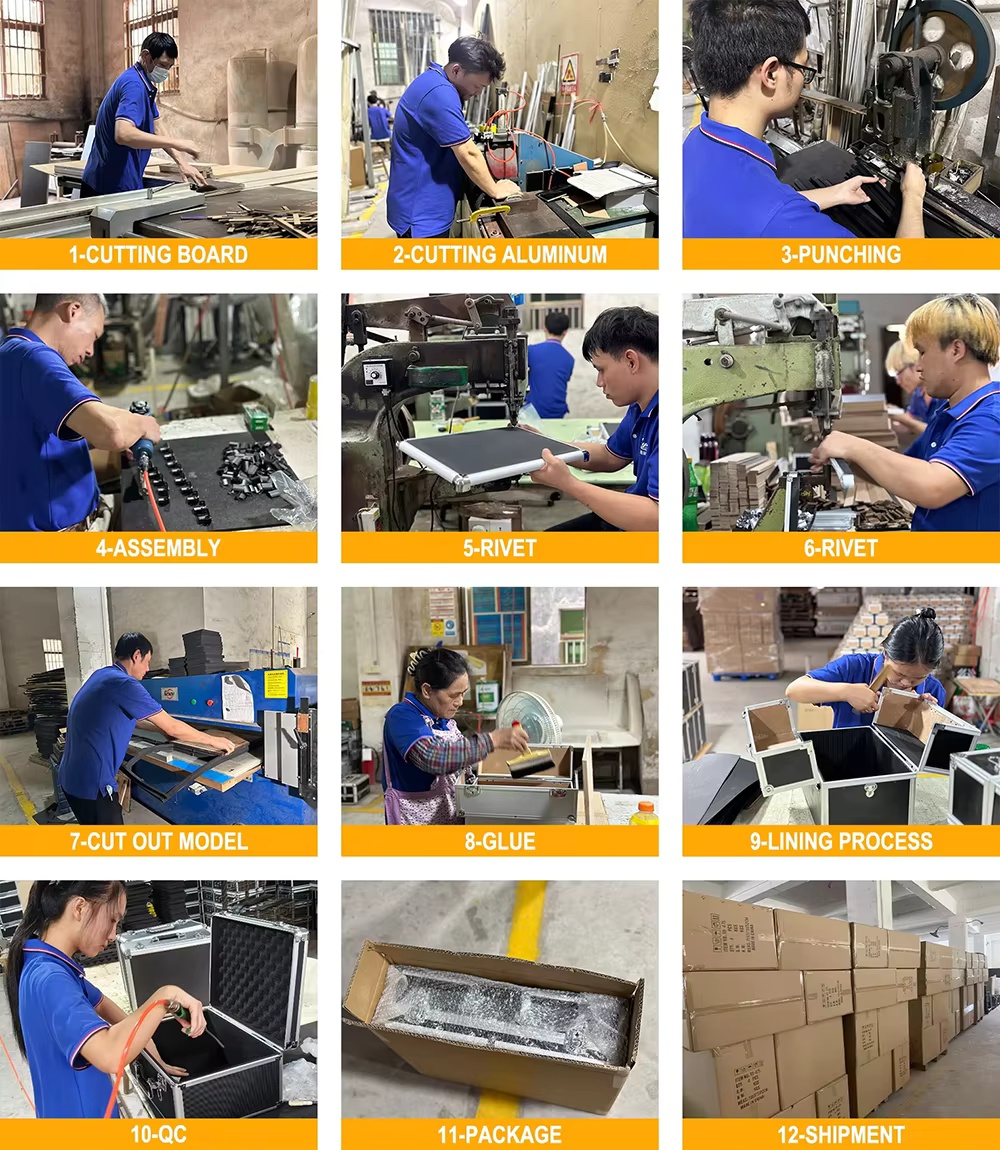

♠ Production Process

1.Cutting Board

Cut the aluminum alloy sheet into the required size and shape. This requires the use of high-precision cutting equipment to ensure that the cut sheet is accurate in size and consistent in shape.

2.Cutting Aluminum

In this step, aluminum profiles (such as parts for connection and support) are cut into appropriate lengths and shapes. This also requires high-precision cutting equipment to ensure the accuracy of the size.

3.Punching

The cut aluminum alloy sheet is punched into various parts of the aluminum case, such as the case body, cover plate, tray, etc. through punching machinery. This step requires strict operation control to ensure that the shape and size of the parts meet the requirements.

4.Assembly

In this step, the punched parts are assembled to form the preliminary structure of the aluminum case. This may require the use of welding, bolts, nuts and other connection methods for fixing.

5.Rivet

Riveting is a common connection method in the assembly process of aluminum cases. The parts are firmly connected together by rivets to ensure the strength and stability of the aluminum case.

6.Cut Out Model

Additional cutting or trimming is performed on the assembled aluminum case to meet specific design or functional requirements.

7.Glue

Use adhesive to firmly bond specific parts or components together. This usually involves the reinforcement of the internal structure of the aluminum case and the filling of gaps. For example, it may be necessary to glue the lining of EVA foam or other soft materials to the inner wall of the aluminum case through adhesive to improve the sound insulation, shock absorption and protection performance of the case. This step requires precise operation to ensure that the bonded parts are firm and the appearance is neat.

8.Lining Process

After the bonding step is completed, the lining treatment stage is entered. The main task of this step is to handle and sort out the lining material that has been pasted to the inside of the aluminum case. Remove excess adhesive, smooth the surface of the lining, check for problems such as bubbles or wrinkles, and ensure that the lining fits tightly with the inside of the aluminum case. After the lining treatment is completed, the interior of the aluminum case will present a neat, beautiful and fully functional appearance.

9.QC

Quality control inspections are required at multiple stages in the production process. This includes appearance inspection, size inspection, sealing performance test, etc. The purpose of QC is to ensure that each production step meets the design requirements and quality standards.

10.Package

After the aluminum case is manufactured, it needs to be properly packaged to protect the product from damage. Packaging materials include foam, cartons, etc.

11.Shipment

The last step is to transport the aluminum case to the customer or end user. This involves arrangements in logistics, transportation, and delivery.

The production process of this barber case can refer to the above pictures.

For more details about this barber case, please contact us!