Medical Case

Portable Aluminum Medical Case Medicine Storage First Aid Box

♠ Product Description

Durable Aluminum Construction

Crafted from high-quality aluminum frame, this medical case offers excellent durability and protection for your medical supplies. It’s resistant to impact, moisture, and corrosion, making it ideal for long-term use in various environments. The sleek exterior also provides a professional appearance, suitable for clinics, homes, or on-the-go emergency responders.

Organized and Spacious Interior

The case features a well-organized interior with removable compartment, allowing you to neatly store medicine, bandages, tools, and other essentials. The compartment helps categorize items for easy access during emergencies. Whether you're storing daily medication or a full first aid kit, this layout ensures everything stays in place and ready to use.

Secure and Portable Design

Equipped with a reliable locking mechanism, this case keeps medical contents safe from tampering or accidental access. The ergonomic handle and lightweight structure make it easy to carry, whether at home, in a vehicle, or during travel. It's a dependable option for caregivers, first responders, or families needing secure medical storage on the move.

♠ Product Attributes

| Product Name: | Medical Case |

| Dimension: | We provide comprehensive and customizable services to meet your diverse needs |

| Color: | Silver / Black / Customized |

| Materials: | Aluminum + ABS panel + Hardware |

| Logo: | Available for silk-screen logo / emboss logo / laser logo |

| MOQ: | 100pcs( Negotiable ) |

| Sample Time: | 7-15 days |

| Production Time: | 4 weeks after confirmed the order |

♠ Product Details

Handle

The handle provides a comfortable and secure grip, allowing users to carry the case with ease. It’s designed to support the full weight of the loaded box, making transportation simple and convenient—ideal for emergencies, travel, or daily use at home or work.

Hinge

The hinge connects the lid to the base of the case, enabling smooth opening and closing. It ensures long-term durability and allows the lid to stay securely in place when open. Quality hinges also help prevent misalignment and wear over time, maintaining the case’s structural integrity.

Lock

The lock secures the contents of the case, protecting medical supplies from unauthorized access, especially important for homes with children or in shared environments. It adds an extra layer of safety and ensures the case stays closed during transport, reducing the risk of spills or damage.

Interior Structure

The interior structure is designed for organized storage, including removable compartments. It helps separate and secure different types of medical items—such as medicine bottles, bandages, and tools—making them easy to find quickly in an emergency. This layout also prevents items from shifting or breaking during movement.

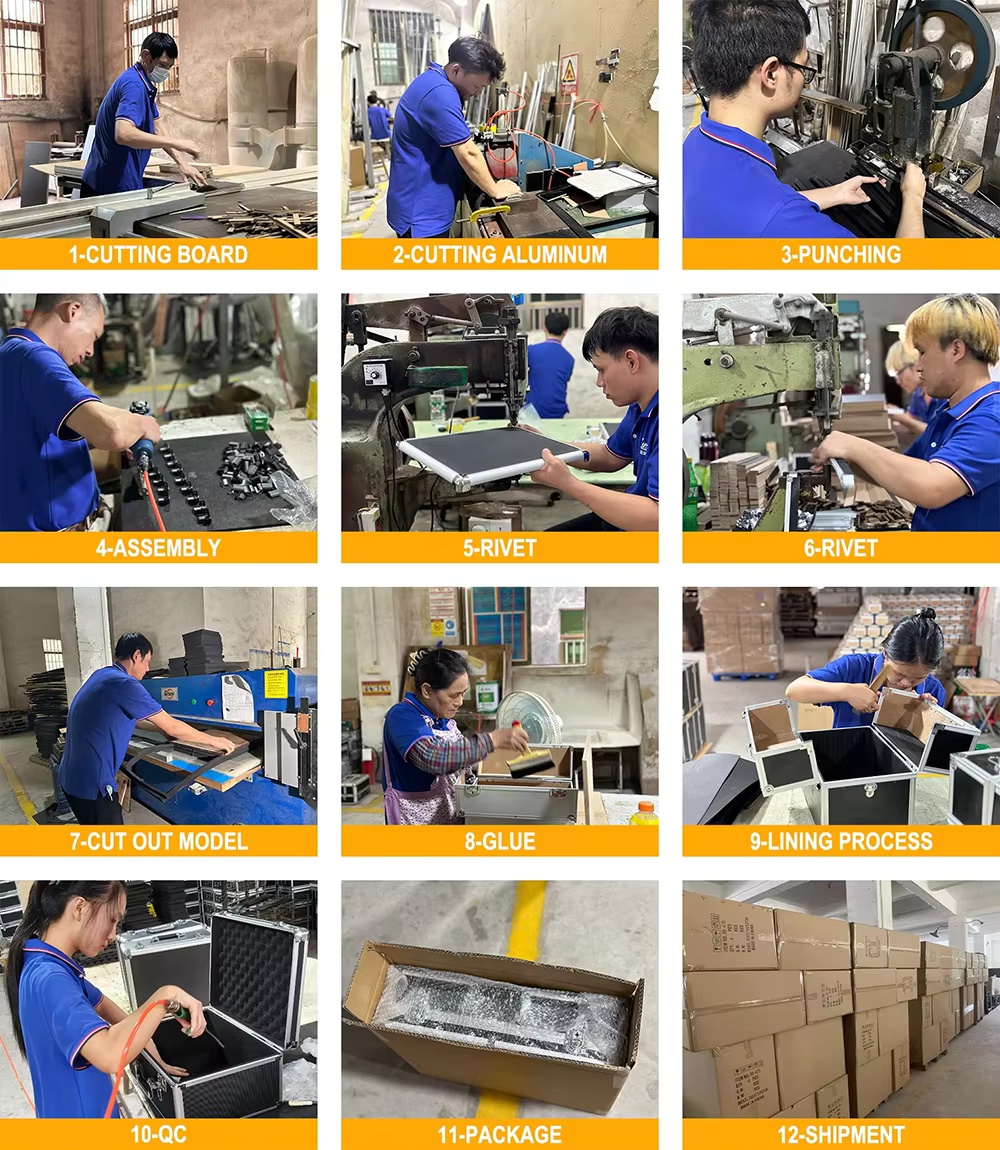

♠ Production Process

1.Cutting Board

Cut the aluminum alloy sheet into the required size and shape. This requires the use of high-precision cutting equipment to ensure that the cut sheet is accurate in size and consistent in shape.

2.Cutting Aluminum

In this step, aluminum profiles (such as parts for connection and support) are cut into appropriate lengths and shapes. This also requires high-precision cutting equipment to ensure the accuracy of the size.

3.Punching

The cut aluminum alloy sheet is punched into various parts of the aluminum case, such as the case body, cover plate, tray, etc. through punching machinery. This step requires strict operation control to ensure that the shape and size of the parts meet the requirements.

4.Assembly

In this step, the punched parts are assembled to form the preliminary structure of the aluminum case. This may require the use of welding, bolts, nuts and other connection methods for fixing.

5.Rivet

Riveting is a common connection method in the assembly process of aluminum cases. The parts are firmly connected together by rivets to ensure the strength and stability of the aluminum case.

6.Cut Out Model

Additional cutting or trimming is performed on the assembled aluminum case to meet specific design or functional requirements.

7.Glue

Use adhesive to firmly bond specific parts or components together. This usually involves the reinforcement of the internal structure of the aluminum case and the filling of gaps. For example, it may be necessary to glue the lining of EVA foam or other soft materials to the inner wall of the aluminum case through adhesive to improve the sound insulation, shock absorption and protection performance of the case. This step requires precise operation to ensure that the bonded parts are firm and the appearance is neat.

8.Lining Process

After the bonding step is completed, the lining treatment stage is entered. The main task of this step is to handle and sort out the lining material that has been pasted to the inside of the aluminum case. Remove excess adhesive, smooth the surface of the lining, check for problems such as bubbles or wrinkles, and ensure that the lining fits tightly with the inside of the aluminum case. After the lining treatment is completed, the interior of the aluminum case will present a neat, beautiful and fully functional appearance.

9.QC

Quality control inspections are required at multiple stages in the production process. This includes appearance inspection, size inspection, sealing performance test, etc. The purpose of QC is to ensure that each production step meets the design requirements and quality standards.

10.Package

After the aluminum case is manufactured, it needs to be properly packaged to protect the product from damage. Packaging materials include foam, cartons, etc.

11.Shipment

The last step is to transport the aluminum case to the customer or end user. This involves arrangements in logistics, transportation, and delivery.

The production process of this medical case can refer to the above pictures.

For more details about this medical case, please contact us!